Ansys Fluent Day 2, Turbulence & Meshing

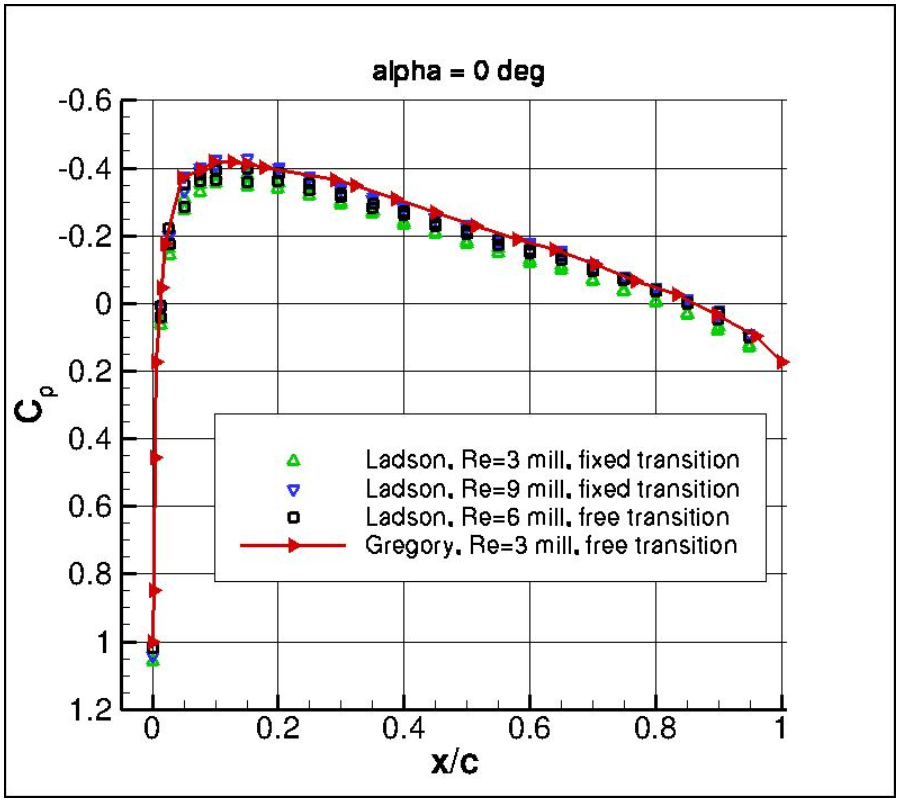

Turbulence Validation: NACA0012 Airfoil

- Let's confirm the k-omega SST Turbulence model in Fluent

- From Workbench, drag/drop a Fluent Component (not Fluent Meshing)

- Open in 2D mode, and import the NACA 0012 Airfoil here: NACA0012_0.msh

- (Reference: https://turbmodels.larc.nasa.gov/naca0012_val.html)

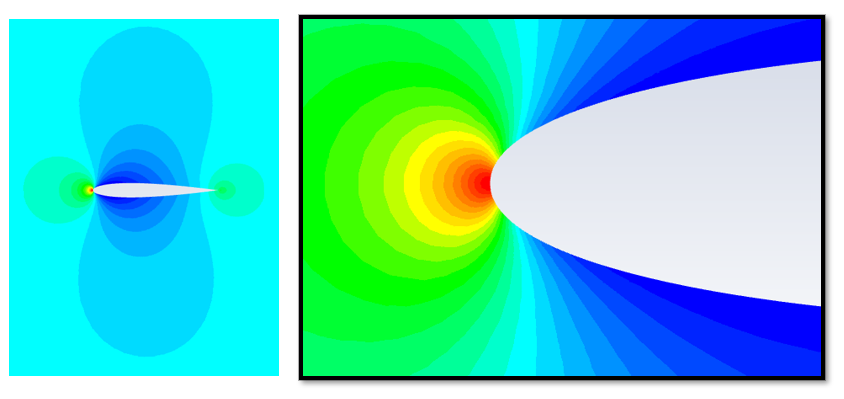

Post-Process:

- Review the velocity, note the distance between the airfoil and the model limits

- Check for Mesh Independence

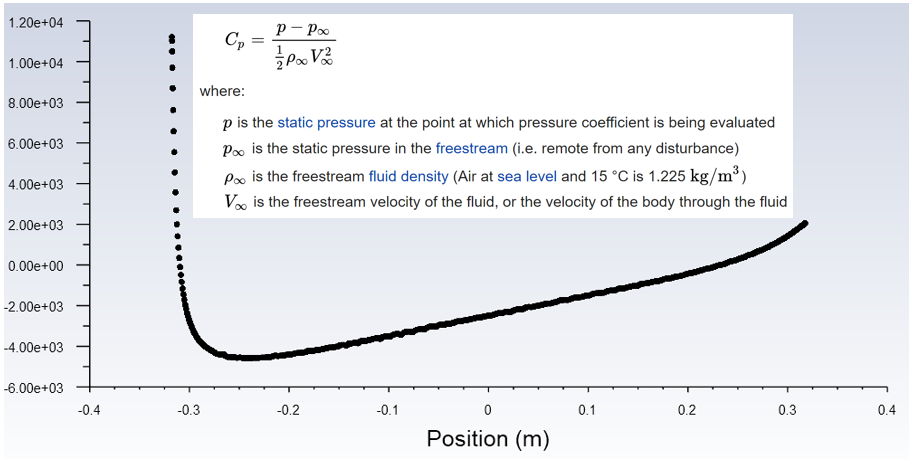

- Create a Pressure Coefficient (Cp) Contour

Post Process:

- Discuss the definition of Cp

- Plot the Cp along the top edge of the airfoil

- Correlate the Cp ratio to the NASA Data

- Report: Vertex Max, Pressure, Cp

- Report: Vertex Min, Pressure, Cp

- Report: Expression = Max Cp/Min Cp

- The answer should be 0.41!

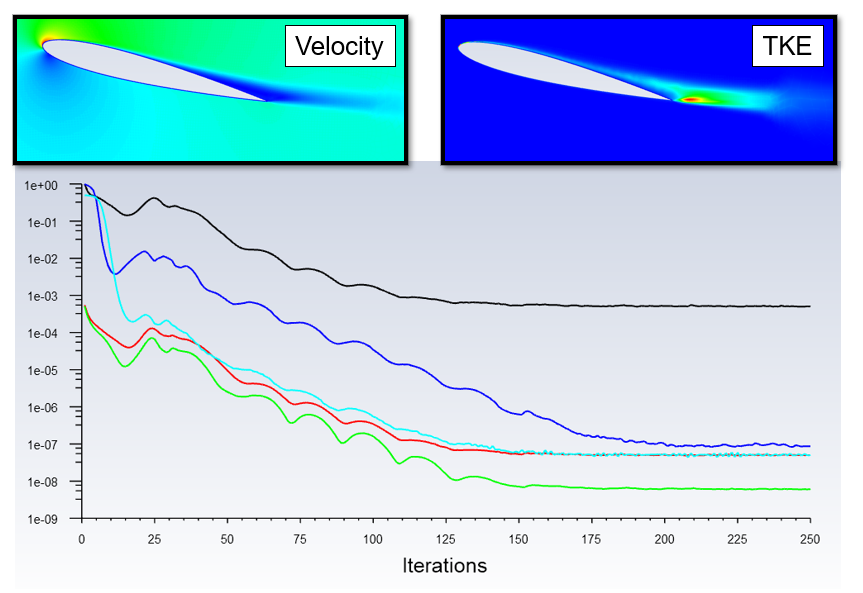

Investigate:

- Let's use Fluent to determine the stall Angle of Attack of the NACA0012 airfoil.

- During this investigation:

- Post-process the turbulence values

- Observe the convergence for signs of oscillation

- Download the pre-modeled mesh files here: NACA0012_aoa_sweeps.zip

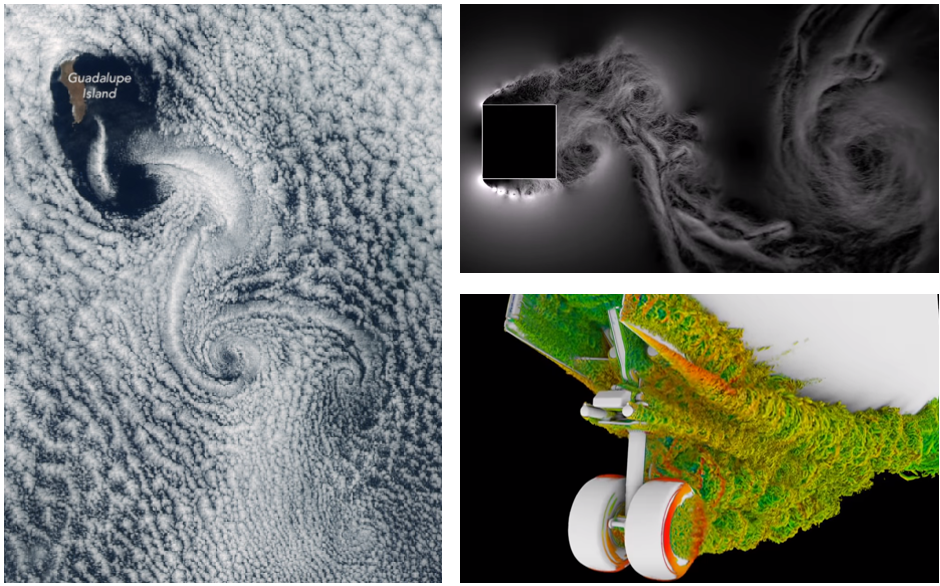

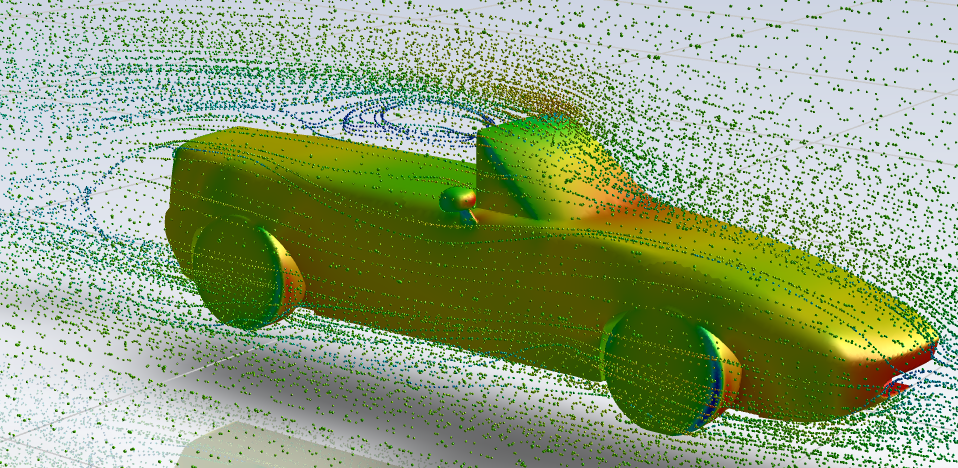

Turbulence:

- “Unpredictable” changes in the flow characteristics: velocity and pressure

- Characterized by vortices (eddies) within the flow

- Vortices can be large or small

- Vortices can be fast or slow

- Vortices can live for a long time for a short time

- This all happens at the same time

- Turbulence is constantly changing in Length AND Time

Turbulence:

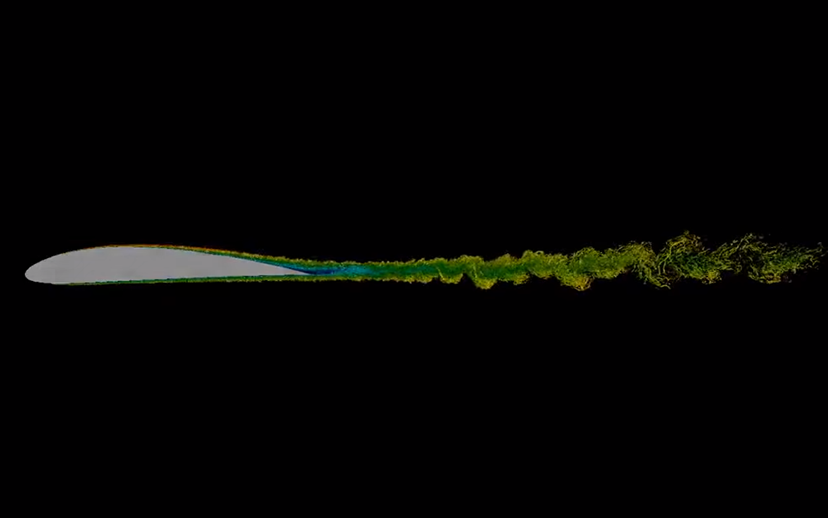

- Very computationally expensive, so its "modeled, not meshed"

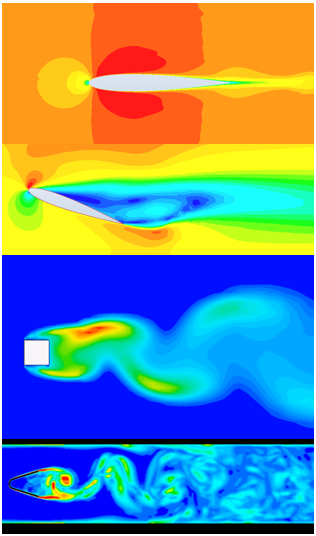

- CFD codes are put in categories based on how they handle Turbulence:

- RANS – Reynold’s Averaged Navier Stokes (Time-Averaged Turbulence)

- DES – Detached Eddy Simulation (Combo of RANS & LES)

- LES – Large Eddy Simulation (Ignores small vortices)

- DNS – Direct Numerical Simulation (Resolving flow on time and length scales!) (EXAMPLE)

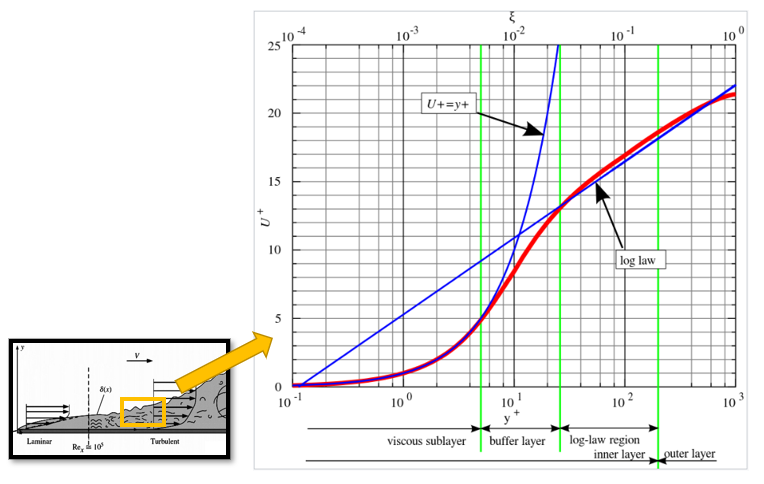

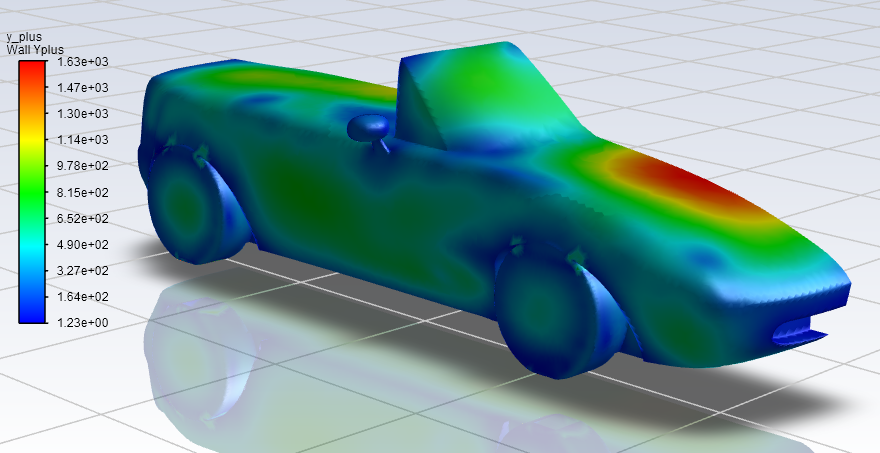

Reynolds Averaged Navier-Stokes (RANS):

- In the boundary layer, the mesh must be accurately sized (not too big, and not too small!)

- The Law of the Wall:

- “The average velocity of turbulent flow is proportional to the log of the distance from the wall”

- We use the “y+” value to determine the proper wall layer height:

- y+ = y * Friction Velocity/Kinematic Viscosity

- y+ = distance from the wall * flow characteristics/fluid properties

Reynolds Averaged Navier Stokes (RANS):

- k-epsilon: Standard turb model used in many applications (30<y+<300)

- SST k-omega: Recommended for external Aero, detached flows (1<y+<10)

- SAS: Vortex shedding, variable wake

- DES: Separation/High Reynold’s Number

- RNG: Reattachment (Flow over a backward facing step)

- Low Re k-e: 1,500<Re<5,000, and “jets”

- Mixing Length: Designed for Internal Natural Convection (gases)

- Eddy Viscosity: For low speed turbulent flow if the k-epsilon won’t work…

- GEKO – Generalized K-Omega

- More Information in Ansys Help

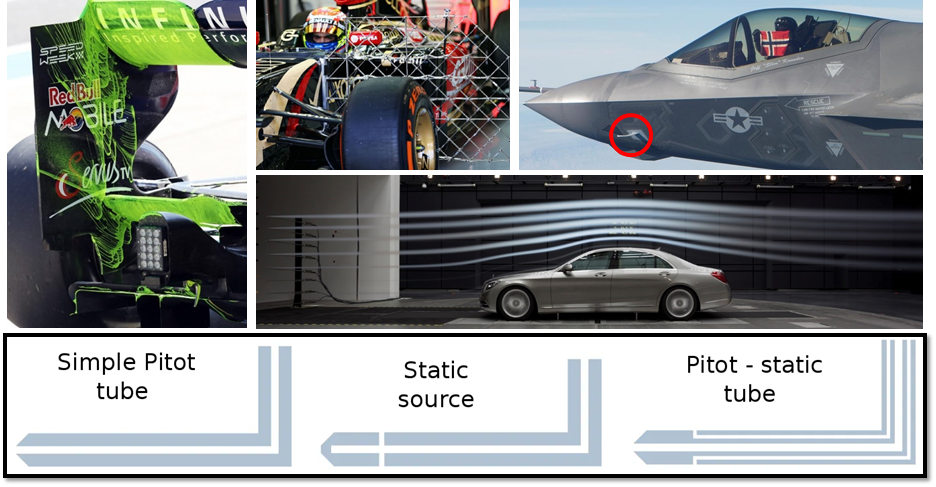

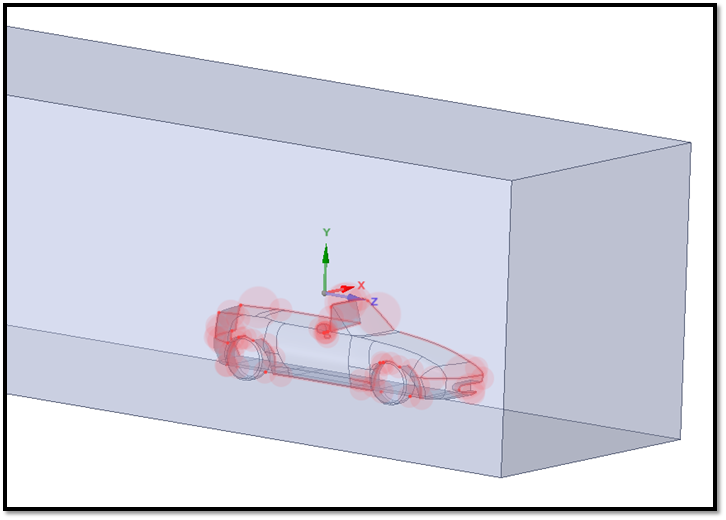

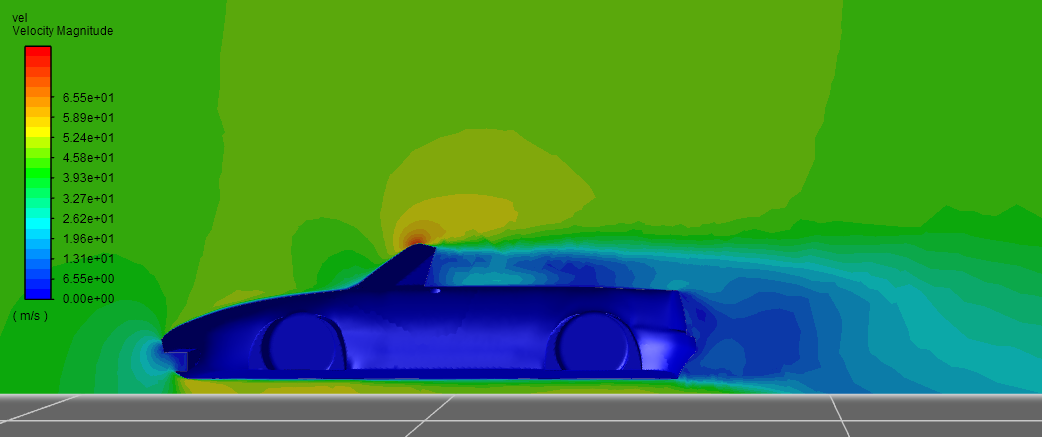

Steady State Subsonic External Flow - The Vehicle in Ground Effect

- Performance characteristics are defined by the forces acting on the vehicle

- Drag, Thrust, Lift, Gravity

- Lift forces come from: Fluid being redirected and the Bernoulli Effect

- Drag Forces come from:

- Form: Creation of turbulence and low pressure zone in wake

- Skin Friction Drag: Viscous Shear forces in Boundary Layer

- Lift-Induce Drag: Creation of turbulent vortices in the wake

Steady State Subsonic External Flow - The Vehicle in Ground Effect

- Fdrag = Cd*(1/2*rho*V^2)*A

- Flift = Cl*(1/2*rho*V^2)*A

- Typically, Cd & Cl are obtained experimentally

- Cd is relatively easy to research for passenger vehicles ~0.30 (wiki)

- Cl not so much… (so let’s use CFD!)

- Simple Convertible Calcs:

- A = 17.7 ft2

- Cd = 0.38 (Top down)

- V = 100mph

Prepare:

- Use SpaceClaim to prepare the geometry for meshing

- Fix "dirty" CAD

- Extra Edges; Inexact Edges

- Create Named Selections

- Download model here: miata_air.x_t

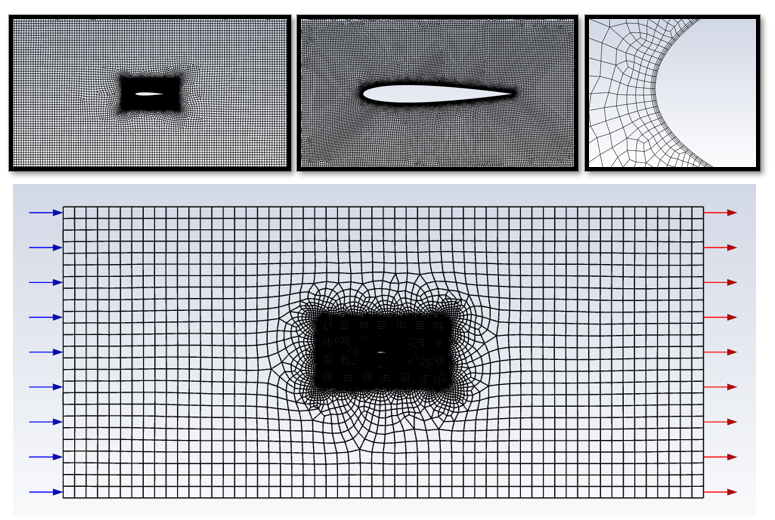

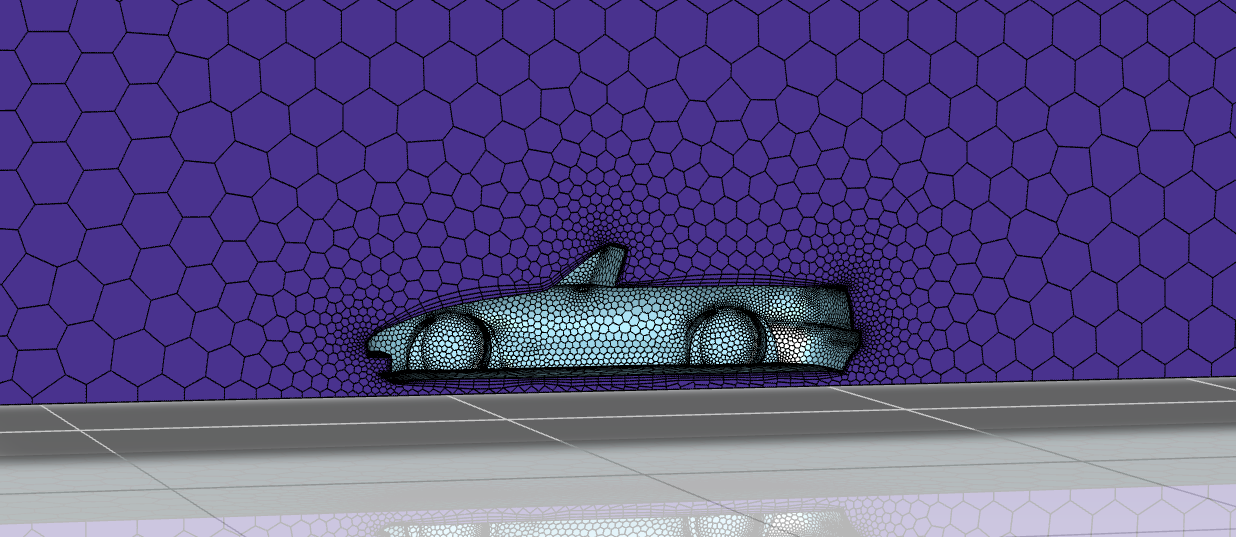

Mesh:

- Import into the Watertight Workflow

- Create a volume mesh using the default mesh sizes

- Improve the mesh quality as needed

- Help: Fluent User Guide 24.2 Quality Measurements

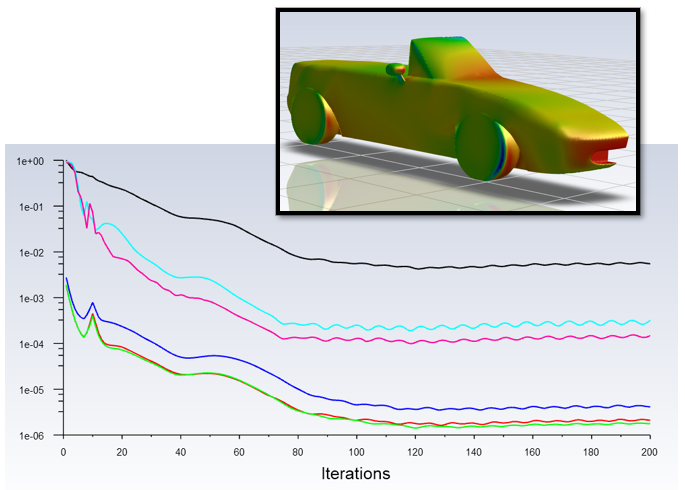

Setup:

- Inlet - 100 mph

- Start with K-Epsilon Turbulence model

- 30<y+<300

- Start with 1e-3 residuals

- Start with 200 iterations

- Solve & Review

Refine:

- The turbulent wake needs to be resolved finer

- Utilize a Body of Interest (BOI) in SpaceClaim & Fluent Meshing

- What surfaces need a surface refinement?

Assess for Accuracy in Turbulence Modeling:

- Review the y+, does it correspond to our Turbulence Model?

- Calculate the drag force, does it correlate to the published Cd value?

- Would a K-Omega turbulence model be more accurate?

Optimize:

- Can we use the results of this analysis to make the design better?

- How might we reduce the drag?

- Pick an idea and try it!

Brief Overview on CFD Validation:

- In a Wind Tunnel

- Quantitatively: Measuring pressure with a Pitot Tube

- Qualitatively: Using smoke trails

- In the real world

- Quantitatively: Pitot tubes, Coast Down test

- Qualitatively: Flow viz paint

© Fastway Engineering. All Rights Reserved. May not be duplicated without express written consent.