For Market-Leading Manufacturers

Custom and Advanced FEA Training

Public Training

Fastway Engineering training focuses on the fundamentals of Statics, Kinematics, and Fluid Dynamics using the latest FEA and CFD software. These instructor-led classes are the perfect mix of Technical Theory and Practical Application. No matter what level your designers and engineers are at, they'll walk away with more confidence and better, more optimized designs. Being a better designer means being a better decision maker.

We help engineering teams make better decisions by refreshing the fundamentals, while catching up on the latest product development tools. Interested in training your engineering team in the latest CAD/CAE tools from Ansys and PTC Creo? Check out our training classes here.

Private Advanced FEA Training

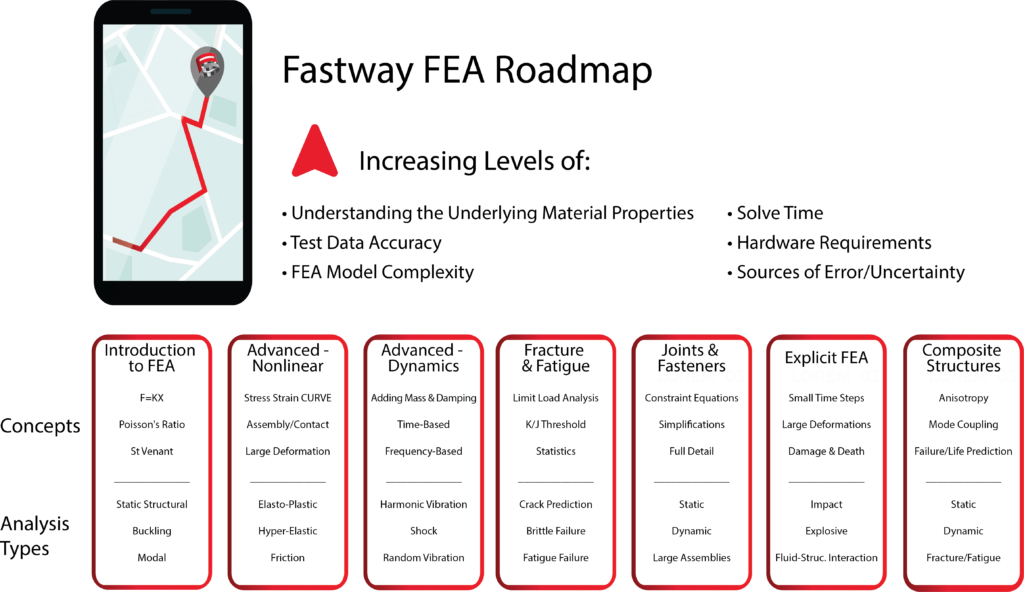

For larger teams, it's more impactful (and economical!) to develop a private class or a custom curriculum specifically tailored to the needs of your product development team. For these classes, we assess the existing capability of the team, then work with business leaders to create a training development plan. This helps establish the technical maturity level that your business has and needs. Click on the roadmap below to see details of concepts and analysis types for Structural FEA that we can deploy into organizations who are ready for the next level. Contact us for more details.

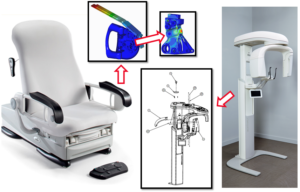

Case Study: Creating a Simulation-Based Culture at Midmark Corporation

Midmark Corporation is a market leader in the Medical, Dental, and Animal Health industries. Midmark uses the latest CAD/CAE best practices to develop innovative products for Diagnostics, Examination, Imaging, Instruments, and Seating. Midmark's portfolio ranges from front-office Lighting and Cabinetry solutions to back-office Mechanicals and Processing and everything in between.

Through Fastway Engineering's Private On-Site and Custom Training Classes, Midmark has climbed the learning curve from Introductory Structural FEA to advanced concepts like Thermal Stress, Fatigue & Fracture, and Topology Optimization. Through this educational process, the engineering team has transformed into a simulation-based product development culture which now includes:

- Consistency through updated internal design processes

- Knowledge re-sharing through internal lunch-and-learns

- Closer correlation between simulation results and empirical test data

- Optimized designs for stiffness, strength, reliability, and cost

- A stronger connection between Engineering objectives and business objectives

Cultural shifts don't happen over night, and Midmark knows that. By creating SMART (Specific, Measurable, Assignable, Realistic, Timely) goals for their design and simulation teams, they continue to advance their Center of Excellence without disrupting the natural ebb and flow of Manufacturing.

With over 100 years of business success, Midmark knows how absolutely critical it is to invest in their employees. Midmark also knows it is equally important to have a team of subject matter experts in their network who they can rely on when it really counts.