Aerospace & Defense Solutions

Tailored Solutions For a A&D Sector Challenges

Proven Success in Aerospace & Defense

- Decades of expertise including teaching NASA, working with DOD Primes, supporting SBIR’s, and qualifying products for MIL-STD-810.

- Uses advanced FEA structural analysis and topology optimization for reliable designs that meet weight quota.

- Experts in low and high-cycle fatigue, fracture analysis, and lifespan prediction for proactive maintenance and failure prevention.

- Specialize in simulating advanced carbon fiber weaves and composite materials for lightweight, high performance panels.

- Proficient in component design and analysis for commercial and defense aerospace, covering fixed and rotary-wing aircraft.

Mission-Critical Simulation Expertise

- Simulation Software Workflows

- Constant Acceleration

- Shock and Random Vibration FEA

- Solar Loading and Radiation

- EMI, EMC, and ESD

- Core Competencies

-

- MIL-STD-810 Analysis

- Structural Dynamics (Shock & Vibration)

- Electronics Cooling (thermal shock, flight profile)

- Designing Shaker Table Test Fixtures

-

Your Challenges

- Minimizing Simulation Error

- Precise Engineering Requirements

- Matching Qualification Test Data

- Difficulty measuring and testing radiation and susceptibility

- Confidence in Simulation accuracy, especially in Opto-Mechanical system design.

- Protect and secure company Intellectual Property (IP) and International Traffic in Arms Regulations (ITAR) controlled data.

Our Solutions

- Use industry best Verification & Validation (V&V) practices

- Meet stringent requirements for components in Harsh Environments

- Use precise (accelerometer, thermocouple) measurement and testing strategies

- Ensure statistical significance throughout the product life cycle, especially in optical system design

- ITAR-Compliant File Transfer and Server Management Processes

Who We Serve

For Small Business

- Expertise in securing funding for small business growth

- Assistance with SBIR grants and technical funding

- Bringing “Prime-Level Processes” to subcontractors

For Startups

- Assistance with SBIR and STTR programs for startup funding

- Help with grant applications and partnership establishment

- Provide strategic engineering support only where needed

A&D Corporations we’ve helped

Grayhill

Jacobs

L3 Technologies

NASA

Otto Engineering

SAIC

Society of Automotive Engineers

TMC Design Corp.

United States Army

Speak With An Application Engineer

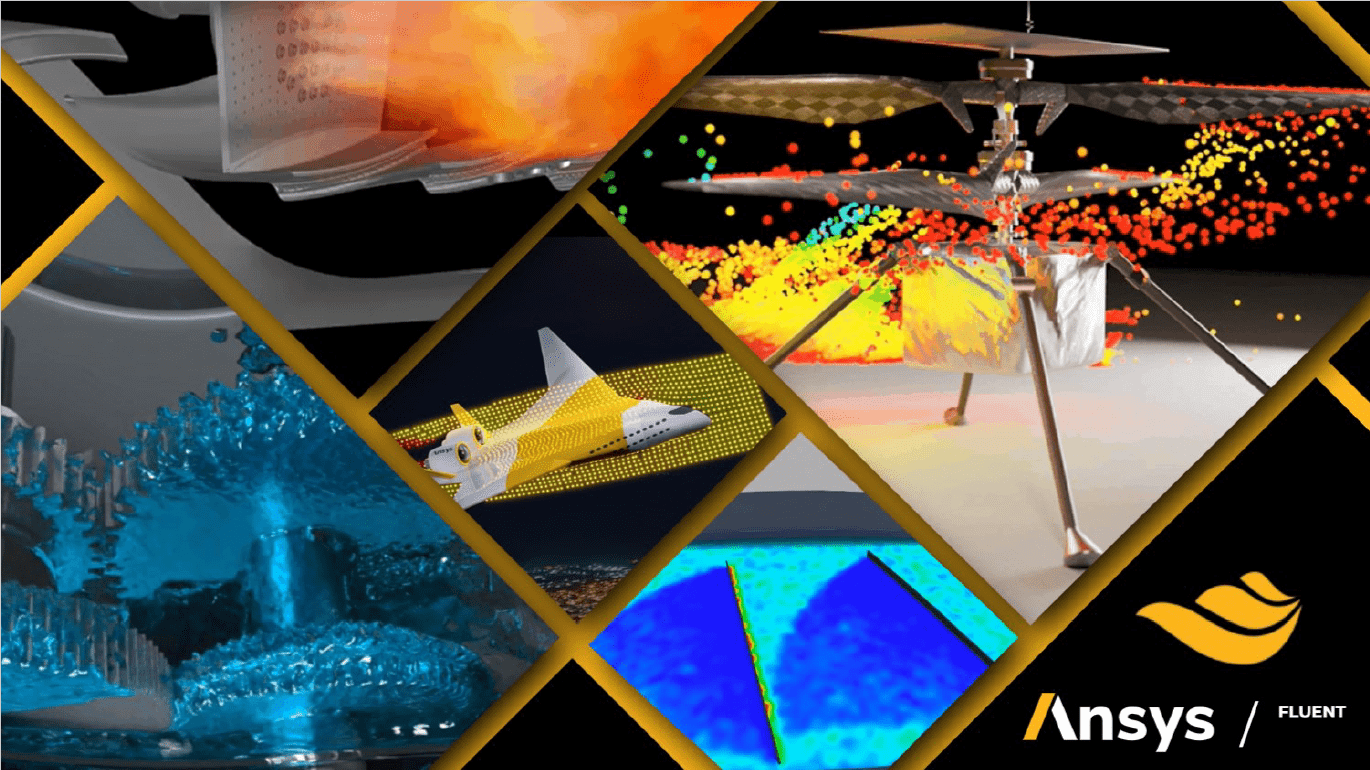

Ansys Aerospace Software Solutions

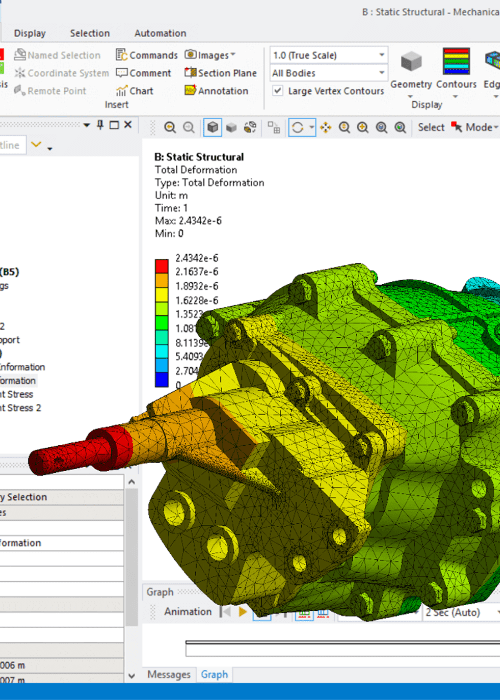

Shock & Vibration FEA

Fastway Engineering excels in Ansys Mechanical software, empowering aerospace engineers to optimize products for strength, weight, and efficiency, streamlining development.

Aero/Thermal Analysis

Fastway Engineering specializes in ANSYS Fluent, providing precise fluid flow analysis customized for aerospace engineering.

Electronics Reliability

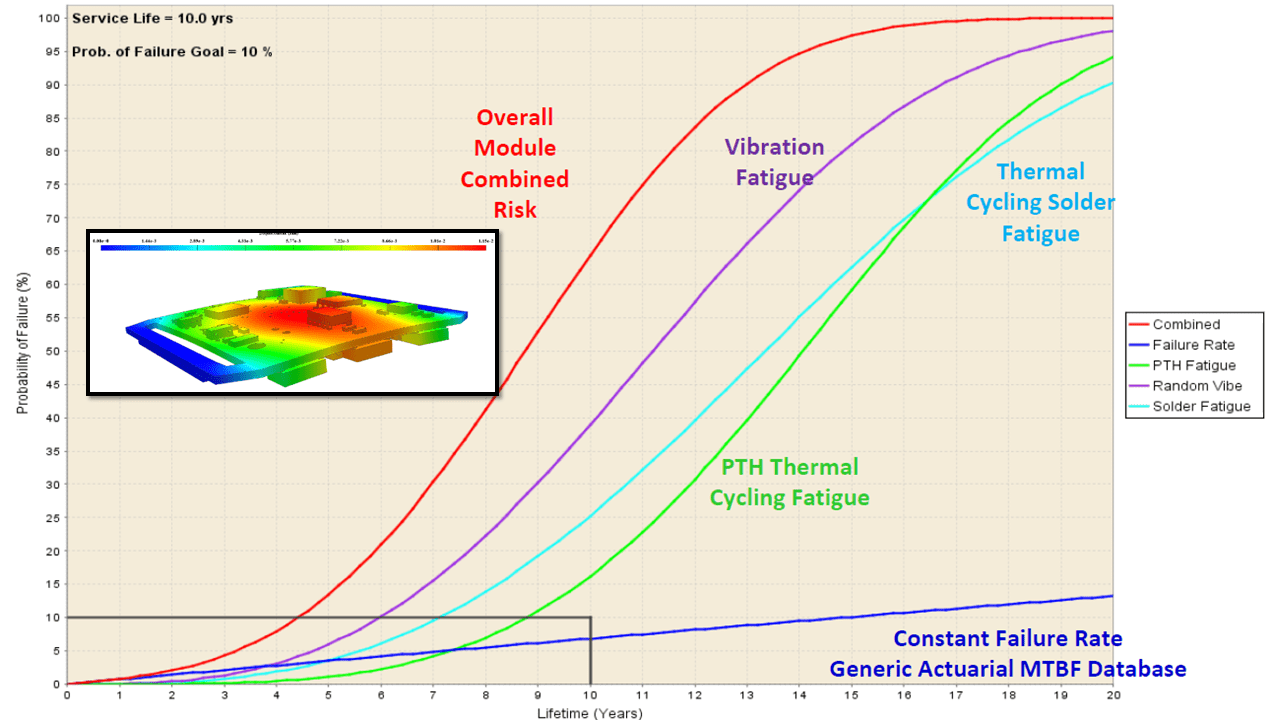

We excel in using ANSYS Sherlock to predict the lifespan and failure modes of printed circuit boards and electrical components, ensuring reliable designs meet A&D industry standards and specifications.

FAQs

Our team uses both time-based and frequency-based FEA workflows and are familiar with the “qualification profiles”, including Sawtooth shock and Random Vibe PSD from MIL-STD-810. Performance and durability are quantified using industry best practice post-processing methods (Rainfall, Miner’s Rule, etc.)

Yes, we specialize in thermal expansion (CTE) and thermal stress analysis to evaluate the effects of temperature variations. Particularly on critical Opto-Mechanical components, we use a variety of CAE workflows to ensure image quality under extreme conditions for the life of the design.

The latest workflows include Generative design and Topology Optimization using Gyroid lattice structures and other Triply Periodic Minimal Surface (TPMS) geometries. Coupled withFEA & CFD, minimal mass and optimal heat transfer rates can be obtained for any application.

Power integrity analysis ensures stable and reliable power distribution within electronic systems, preventing issues like voltage drops, signal distortions, and potential hardware failures. It helps optimize performance, minimize electromagnetic interference, and ensure compliance with industry standards.

Fastway Engineering provides a range of services including shock and vibration analysis, thermal stress simulation, 3D printed heat exchanger design, power integrity analysis, optical system design, electromagnetic field simulation, EMI/EMC testing, electronics cooling solutions, antenna design, and additive manufacturing expertise.

Several analyses are crucial for aerospace optical system design. These include geometric optics analysis to trace light rays, physical optics analysis for wave behavior, tolerancing analysis to maintain performance under variations, thermal analysis for temperature effects, structural analysis for stability, radiometric analysis for accurate radiation detection, and environmental analysis to assess system reliability in various conditions.

Absolutely, we utilize advanced electromagnetic field simulation techniques to analyze and optimize aerospace systems, ensuring compliance with regulatory standards and performance requirements.

We provide tailored solutions for electronics cooling in aerospace systems, utilizing advanced thermal management techniques to optimize performance and reliability.

Yes, we have extensive experience in antenna design for aerospace communication systems, ensuring optimal signal strength and reliability in various operating conditions.