Ansys Fluent Day 1, Intro

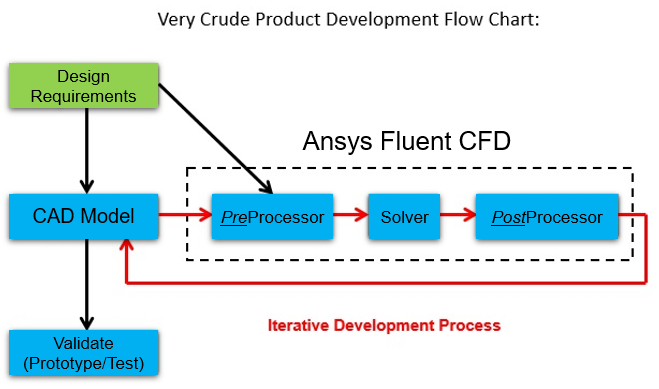

Overview: CFD workflow:

+ CFD (in general): + Ansys:

– Pre-processor – CAD Prep, Meshing, and Setup

– Solver – Solve/Converge

– Post processor – Review Results

(Re)Introduction to Fluids:

- A Fluid is: a substance with no fixed shape that deforms easily under external forces.

- Examples: Liquids and Gases

- Two most common fluids: Air & Water

(Re)Introduction to Fluids:

- Fluid Properties:

- Density, rho = Mass/Volume

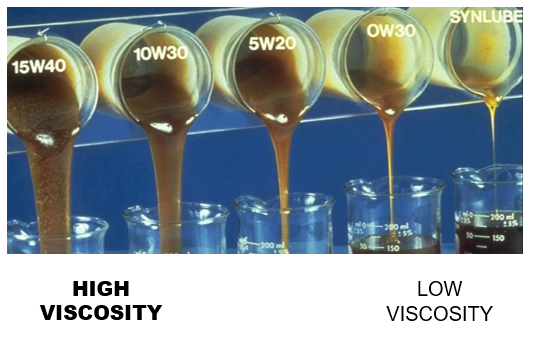

- Viscosity, mu = Resistance to deformation (as a result of shear stress). Commonly called the “thickness” of a fluid.

(Re)Introduction to Fluids:

- Most fluids have a constant Viscosity, and are thus called a “Newtonian Fluid”.

- Special case #1 = Non-Newtonian Fluid: Variable Viscosity, usually as a function of the shear rate (speed with which the fluid is being moved)

- “Shear Thinning”

- Blood

- Ketchup

- “Non Drip Paint”

- “Shear Thinning”

- “Shear Thickening”

- Oobleck

(Re)Introduction to Fluids:

- Flow Characteristics:

- Velocity, V = Distance/Time

- Flow Regimes:

- Subsonic: < 650 mph

- Transonic: 650 – 767 mph

- Supersonic: 767 – 4,000 mph

- Hypersonic: >4,000 mph

(Re)Introduction to Fluids:

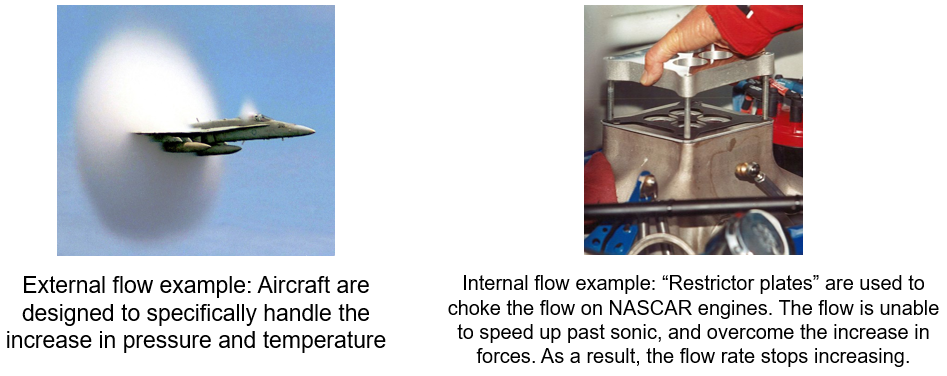

- Speed of Sound = ~767 mph (M=1.0)

- When M>1.0, the air is rapidly compressed (increase in pressure, temperature and density)

- Special case #2 = Compressible Flow: Where fluids (mostly gasses) which exhibit significant changes in density.

(Re)Introduction to Fluids:

- Special case #3 = Inviscid: The viscous forces within the flow are negligible. This can be true for fluid of non-zero viscosity! (e.g. High speed, high atmospheric flow away from a wall).

(Re)Introduction to Fluids:

- Fluid-Flow Characteristics:

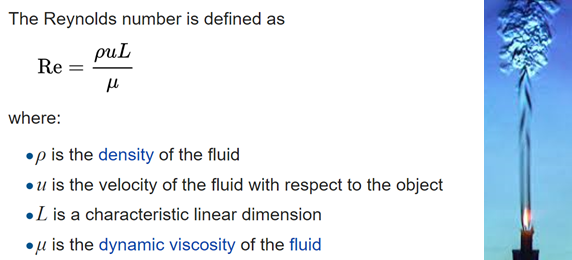

- Reynold’s Number, Re: The ratio of Inertial Forces to Viscous Forces

- Low Re – Laminar

- High Re – Turbulent

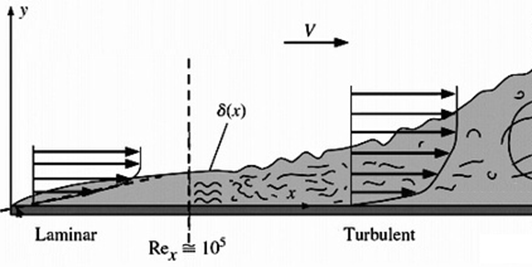

(Re)Introduction to Fluids:

- Boundary Layer

- Region of fluid flow near a wall, where velocity transitions from 0 to V

- Region where viscous forces dominate the flow!

- Critical Reynolds Number, Rex: Where Laminar flow transitions to Turbulent

- Internal Flow: For Flow through a Pipe, Rex = 2300

- External Flow: For Flow over a Plate, Rex = 5x10E5

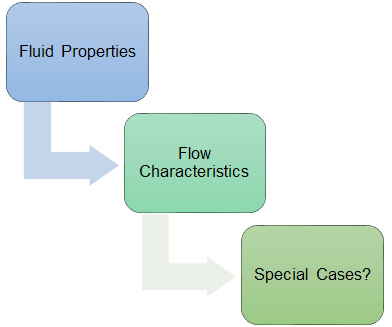

Pre-CFD Checklist:

- What are the fluid properties?

- Density, Viscosity

- What are the flow characteristics?

- Velocity, Reynold’s Number at entrance, where are there Boundary Layers/Walls?

- Do any special cases apply?

- Non-Newtonian?

- Compressible?

- Inviscid?

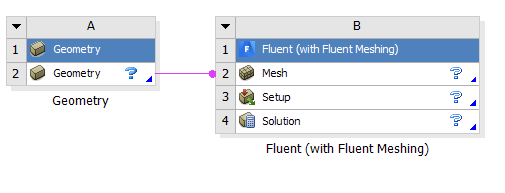

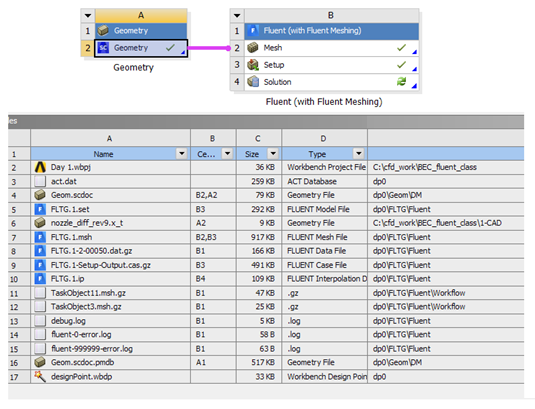

Start:

- Open Workbench

- Drag/Drop a Geometry Component

- Drag/Drop Fluent (with Fluent Meshing)

- Save the Workbench File

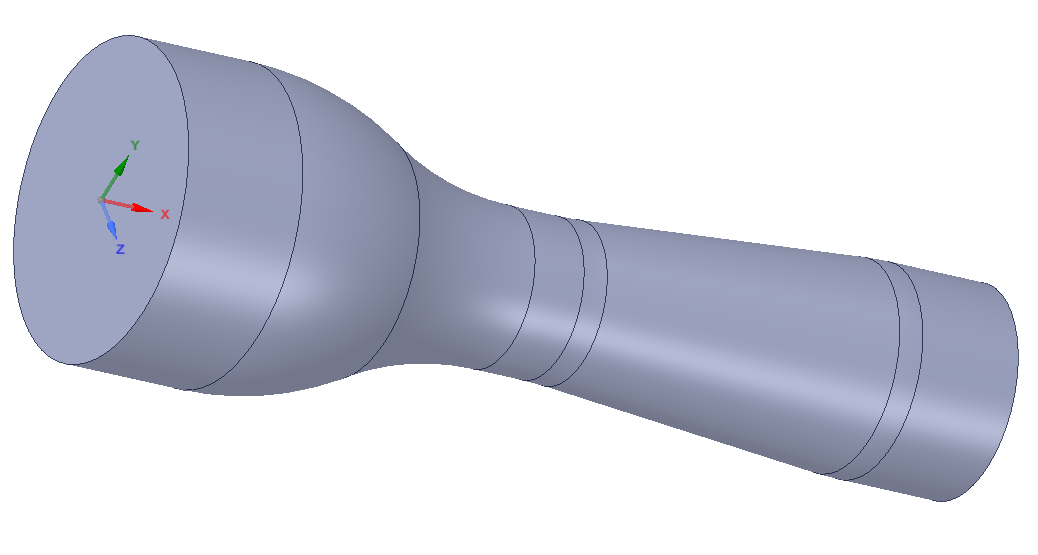

Start:

- Launch SpaceClaim from Workbench

- Import the Nozzle/Diffuser file here: nozzle_diff.x_t

Prepare:

- Use SpaceClaim to prepare the geometry for meshing

- Cut into a "quarter symmetry" model

- Establish Names Selections

- Inlet (Larger Diameter)

- Outlet (Smaller Diameter)

- Symmetry Planes

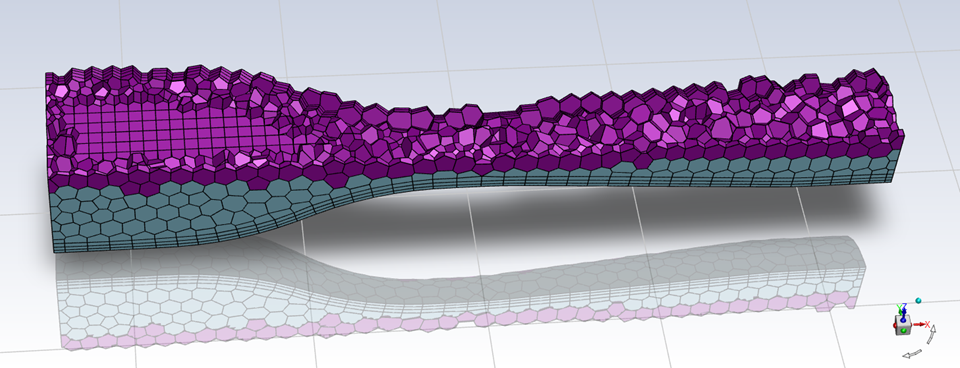

Mesh:

- Import into the Watertight Workflow

- Create a volume mesh using the default mesh sizes

Best Practice:

- Check units in Workbench beforehand

Setup:

- After familiarizing yourself with the interface, audit the model for accuracy

- Physics Models & Materials

- Boundary Conditions

- Set Inlet to 12.5 m/s

Best Practice:

- Check mesh upon entry

Solve the Analysis:

- Set to Laminar & Solve 50 Iterations

- Observe Convergence

- Post Process

- Create a Velocity Contour

- Create Mesh Display

- Create Scene with Velocity & Mesh

Post Process:

- Use various Post Processing Tools:

- Vectors

- Pathlines

- Particle Tracks

- Iso Surfaces

- Create your Favorite Scene

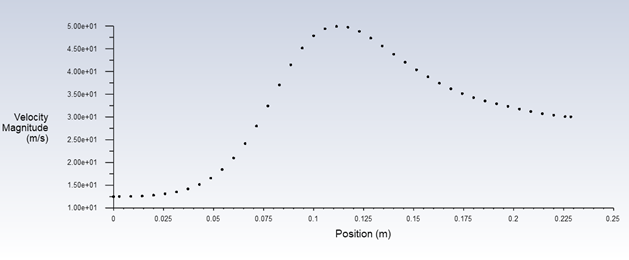

Double Check Your Work:

- How do we know we have the right answer?

- We compare it to “The Math”

- What velocity should we have at the narrow section? The exit?

- Create Reports

- Inlet Flow Rate & Outlet Flow Rate

- Create Plot along pipe Centerline

File Management:

- Don't forget to save often!

- Discuss the different files types

- Mesh

- Case

- Data

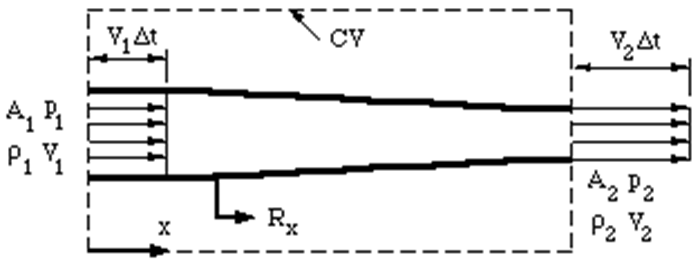

Introduction to CFD Mathematics

- Infinitesimal Fluid Element (Control Volume)

- This volume has both Fluid Properties and Flow Characteristics at a certain point in time

- Density

- Viscosity

- Pressure

- Velocity

- Temperature

Introduction to CFD Mathematics

- Assume the fluid is represented by a “Control Volume”

- Bernoulli says: P + ½*rho*V^2 + rho*g*h = constant

- Pressure, density, Velocity, Gravity, Height

- Additionally:

- A1V1 = A2V2 & P1 – P2 = ½*rho (V2^2 – V1^2)

- So, as Area goes down, Velocity goes up (linearly)

- And as Velocity goes up, Pressure goes down (quadratically)

Modeling Turbulent Flow

- Should we include turbulence?

- Calculate Inlet Re (recall: Turb>2,300+)

- Let’s add turbulence, and solve 100 more iterations

- Why are we able to just continue at the last iteration, even though the entire physics have changed?

- Why did the analysis stop early?

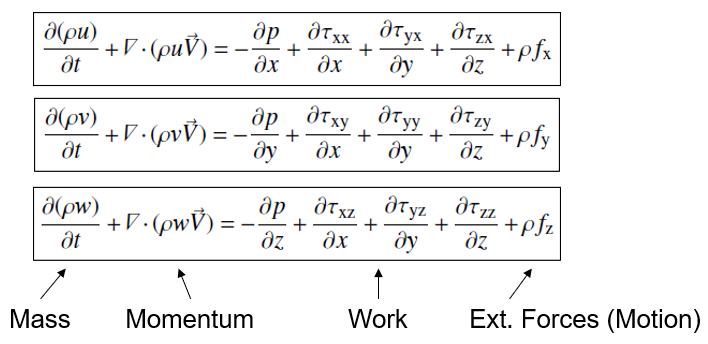

More CFD Mathematics:

- Governing Equations conserve Mass, Momentum, (sometimes) Energy

- These equations must be solved...

- at every iteration

- for every element

More CFD Mathematics:

- Velocity, Mass, Force, and Temperature, are all COUPLED. Thus, the need for an iterative approach.

- We sum this all up to a set of equations called the “Navier Stokes equations (shown here, broken down to the 3 directions (u,v,w), which are velocities in (x, y, z):

Residuals:

- Residuals are the leftover values from each iteration (in the real world, they are zero)

- This is not computationally feasible

- Rule of Thumb:

- Default = .001 (1E-03) – This is for a quick answer.

- Tighter = .0001 (1E-04) – This is for a more accurate answer.

- Fine = .00001 (1E-05) – This is for a solution that you can start to trust.

- Extra Fine = .000001 (1E-06) – This is for an answer that you plan to publish and/or utilize academically.

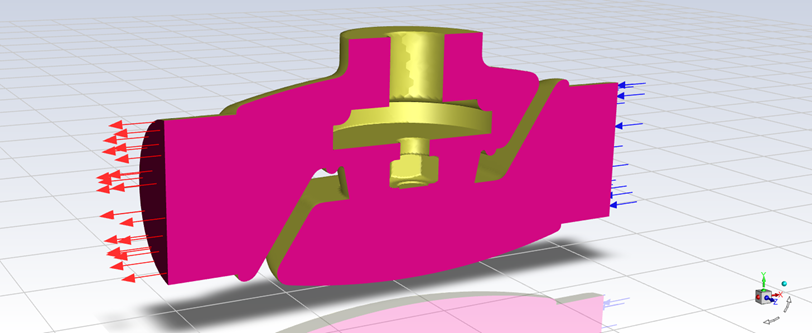

Globe Valve:

- Import, Extract Water Volume, Cut in Half

- Suppress Structure for Physics

- Named Selections: Inlet, Outlet, Symmetry

Download here: globe_valve7_x_t

Mesh:

- Create a Poly-Hex Core Mesh using the Fluent Watertight Workflow

Setup:

- Fluid = Water

- Inlet = 0.002 meter/sec

- Is it turbulent?

- Set Residuals to 1e-4, and solve 100 iterations

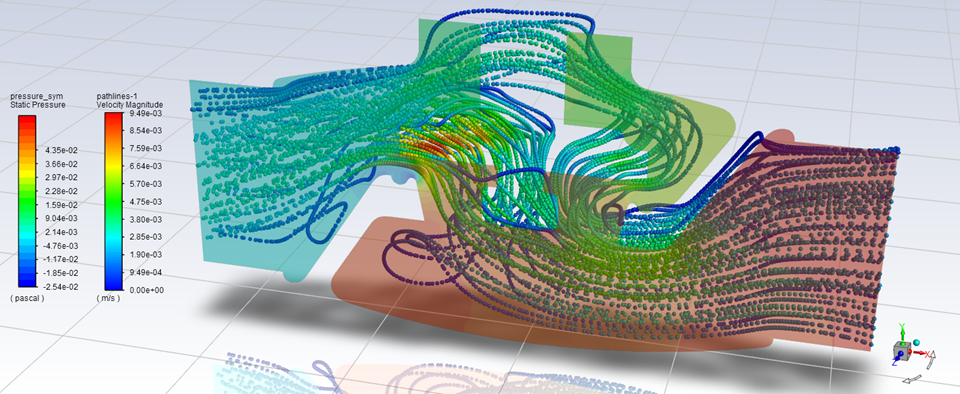

Assess for Accuracy & Quality:

- How can we trust the results?

- Check the velocity at the exit, or at any other location – Compare to Bernoulli's equation

- Check for mesh independence!

- Add a mesh control, and re-solve

- Surface Control

- Gap Elements

Tell the Right Story, and Optimize the Design:

- Create a scene showing the pressure drop and velocity streamlines on the symmetry plane

- Make a design change to minimize the pressure drop in the flow

© Fastway Engineering. All Rights Reserved. May not be duplicated without express written consent.