Ansys Mechanical Day 1, Intro

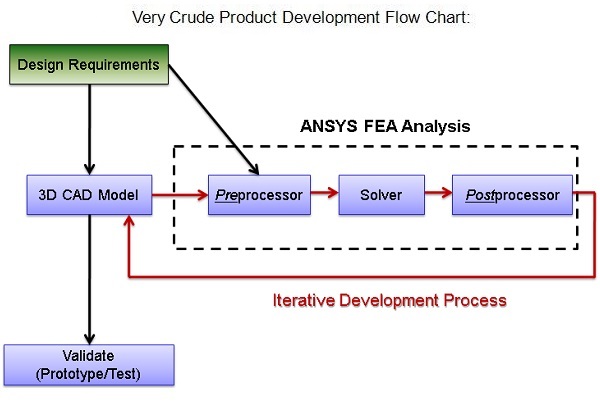

Overview: FEA workflow:

+ FEA (in general): + Ansys Mechanical:

– Pre-processor – Assign Material, Loads/Supports, Mesh

– Solver – Solve the analysis

– Post processor – Review the Solution

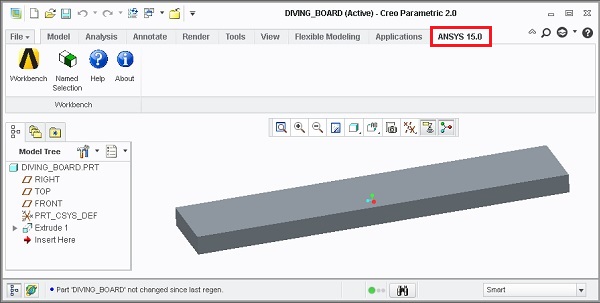

To Start: Create the 6" H x 24" Wide x 120" Long Cantilever Beam geometry shown in the image to the left and import it into the Ansys Workbench.

Note: There are two ways to import into Workbench

- Launch Workbench from within the CAD software (for example, Creo 2.0 is shown here).

- Launch Workbench “standalone”, and import the CAD data.

Walk through both methods.

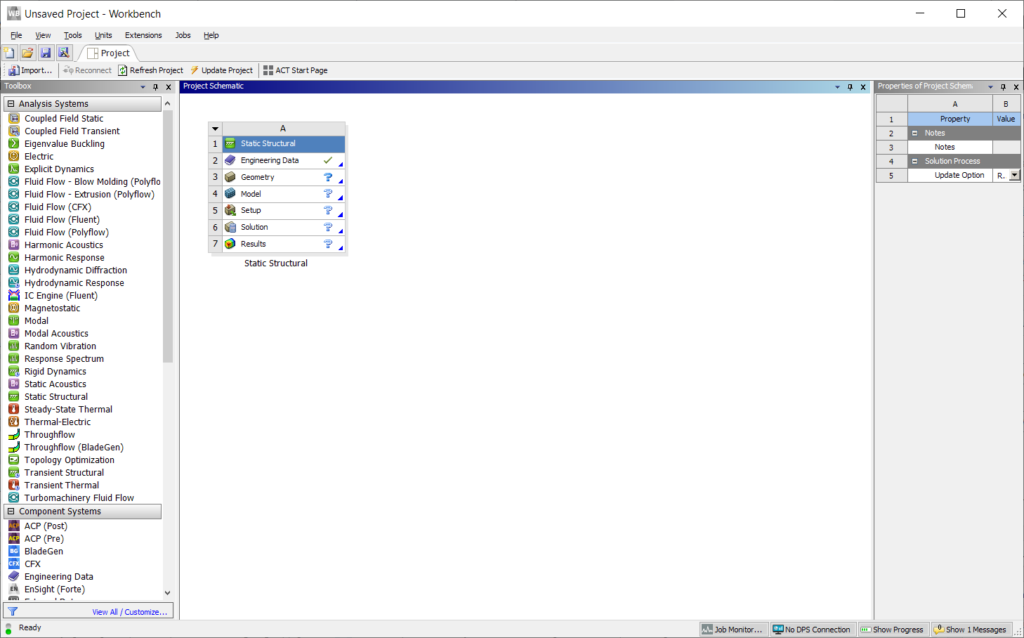

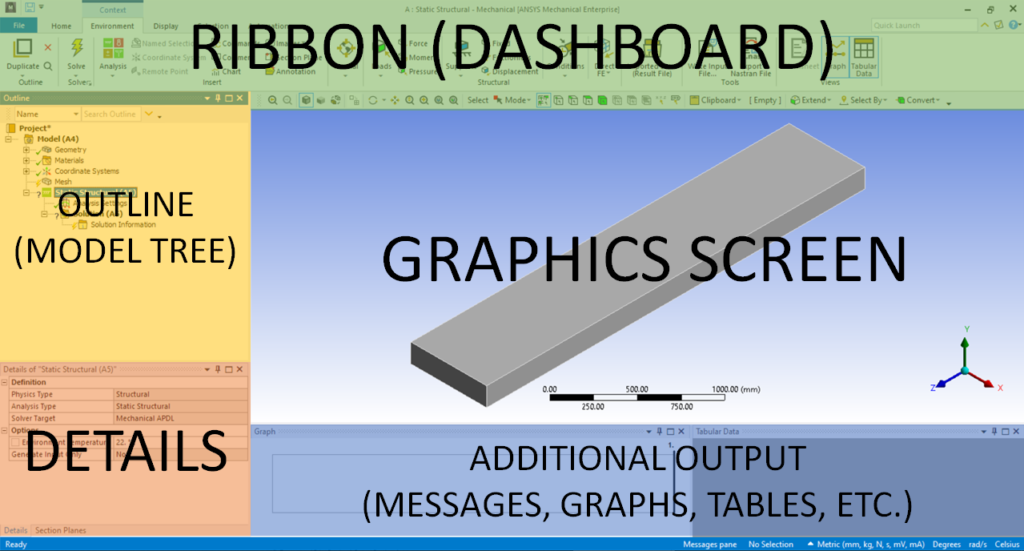

Familiarize Yourself: Ansys Workbench is a Multiphysics simulation tool. Take a tour of the interface.

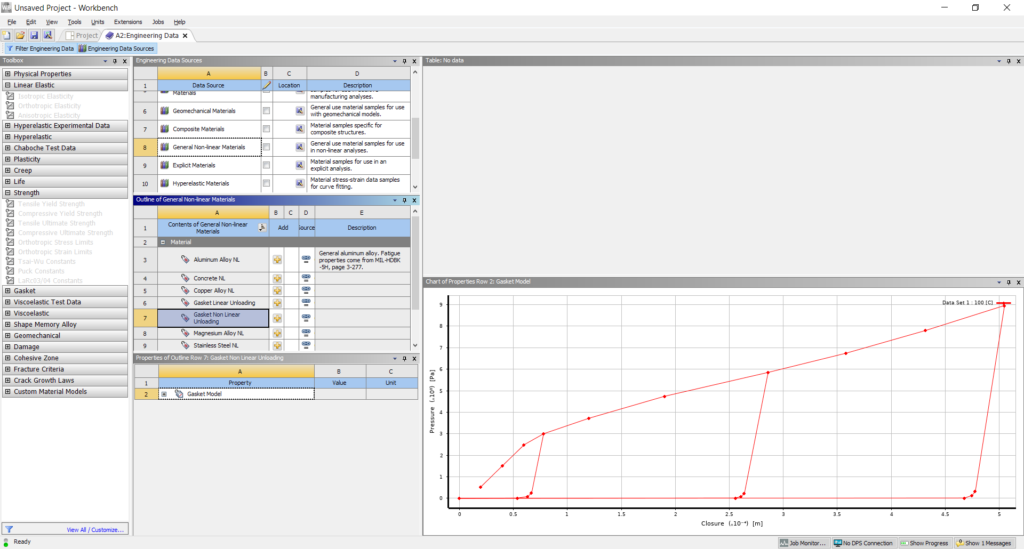

Prepare: Before launching Ansys Mechanical, add AL 6061 to the Engineering Database.

What is Granta?

What is an example of a nonlinear material?

Launch: Open up Ansys Mechanical, and tour the CAD-like Interface

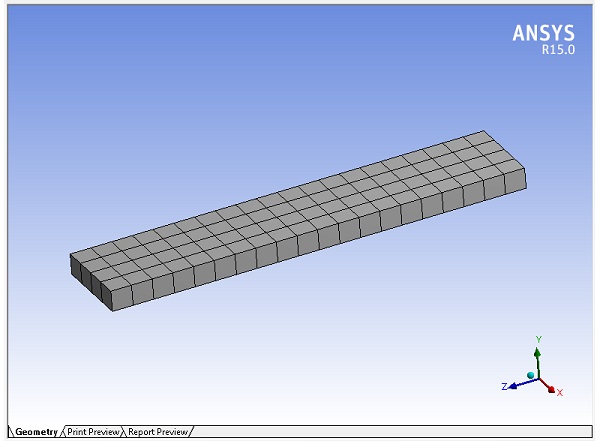

Next: Assign Material, and generate the Mesh

Discuss:

- The Geometry vs. The Mesh

- Hexahedra (aka “Hex” or “Brick”) vs. Tetrahedra (aka “Tet”)

- What are Element Midside Nodes, and how can they be utilized?

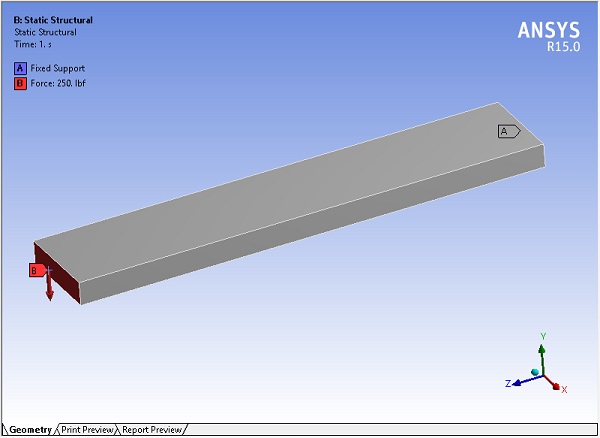

Next: Setup the analysis.

- Fixed Support at the far end of the board

- Force: 250 lbs in the -‘Y’ direction near the end of the board

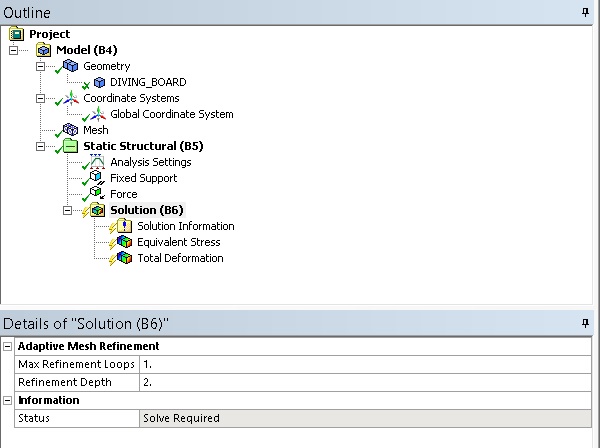

Next: Set up the rest of the analysis so it matches the image to the left.

Note: Pay attention to the status symbols in the outline window. What’s the difference between the Check mark and the Lightning Bolt?

Discuss: The relationship between the Ansys Workbench Environment and the underlying Code (APDL).

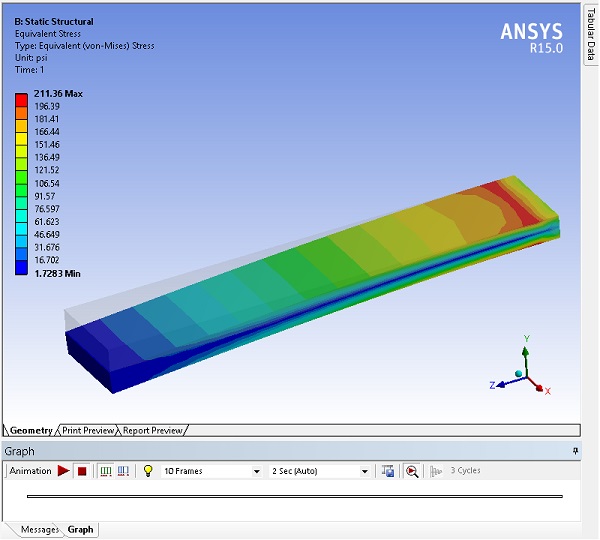

Next: Solve the Analysis, and review the results.

Note: The stress contour through the thickness of the part. Discuss the influence of the mesh.

Try:

- Customizing the Graphics screen (Legend, Display, etc.)

- Playing with the post-processing tools: Images, Animations, and Probes

- Add another 250 lbs load in the -‘X’ direction and rerun the analysis. Add a mesh control to smooth out the stress plot

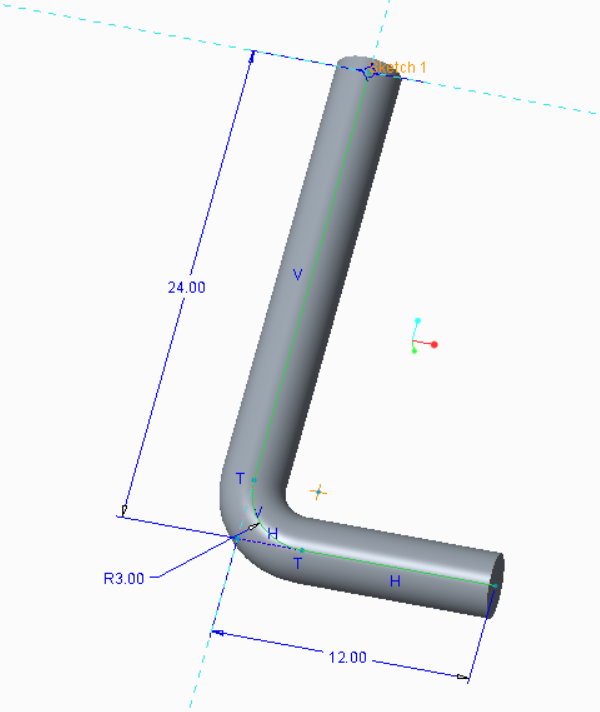

Next: Setup and solve a static structural analysis on the part in the image to the left using the same conditions as the above diving board model.

Note:

- The material is polyethylene

- The diameter of the cross-section is 3.00

- Refine the mesh so the stress contour is smooth

Try:

- Compare to the yield strength of polyethylene

- Change the 12″ long leg to 36″ and rerun the analysis. What’s different about the stress plot? What does this tell you about the possible failure mode?

- Increase the load 10X, and observe the new results. Were the results predictable? Is this good or bad?

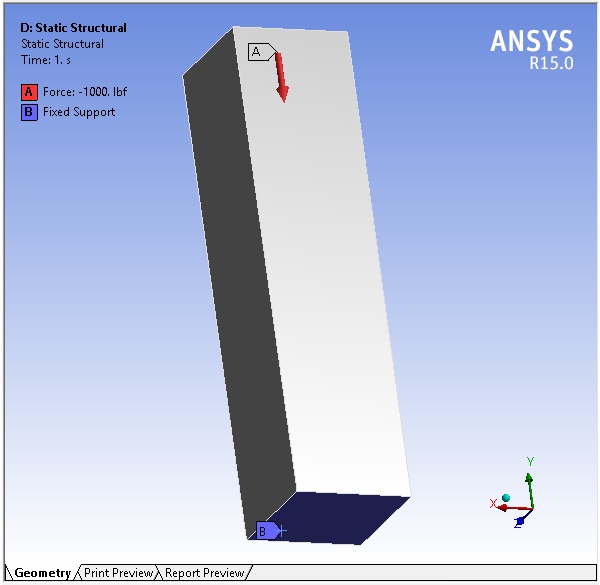

Next:

- Build a stainless steel column that is 5″ by 5″ by 20″.

- Constrain the bottom, and apply a 1,000 lbs compression load on the top.

- After refining the mesh and verifying convergence, review the stress plot, and determine what happened

Try: Constrain the bottom utilizing edges or even vertices, to reduce the stress concentrations.

Discuss: What are weak springs?

Challenge: Change the direction of the load (to tension), and repeat the exercise.

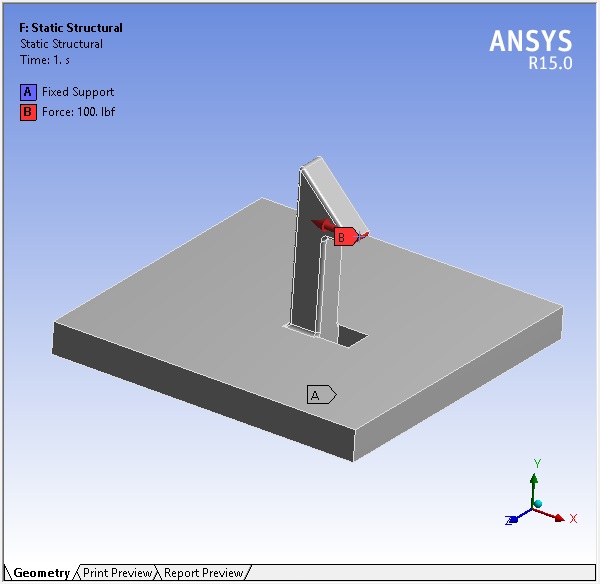

Next: Execute a static analysis on the linked model below. Fix the bottom, and push the clip inwards with a 100 lbs force.

Try:

- Conduct the analysis both with and without the radii on the model. What impact does this have on the mesh count?

- Utilize a mesh controls (such as Sphere of Influence) to ensure mesh independence.

- Instead of a force, push the clip in by 0.1″.

Model: Ansys Clip Model

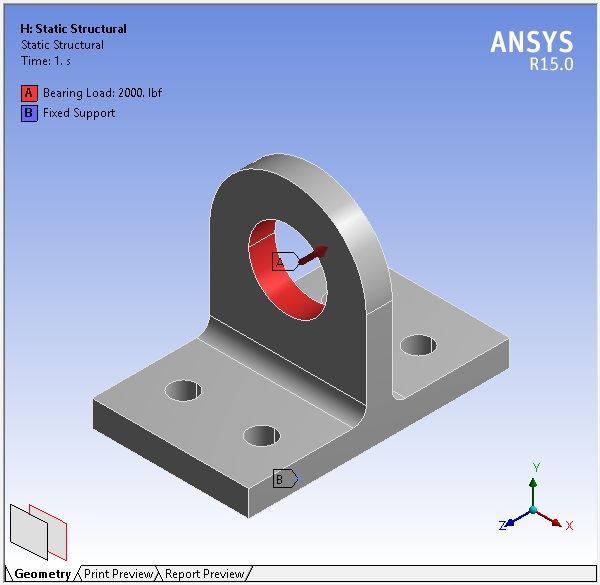

Next: Download the 6061 Aluminum lug model below, and pre-process; fix the bottom surface, and put a 2,000 lbf force at a 45 degree angle as shown in the image. Verify convergence and review the stress.

Try:

- Change the load to a bearing load and constrain the bolt hole surfaces instead as it is more realistic. Compare the stress plots before and after

- Brainstorm other methods of realistically constraining the bolt holes.

- Cut the model in half and rerun the analysis with a symmetry constraint. Are the results identical?

Model: Ansys Lug Model

© Fastway Engineering. All Rights Reserved. May not be duplicated without express written consent.